>> Rubber Preformer Machine and Auxiliary Machines

Rubber Precision Preformer

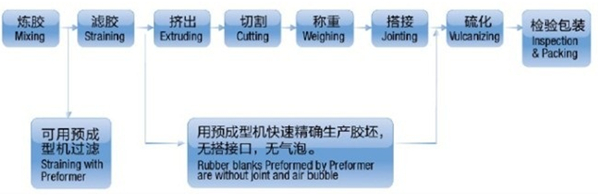

Rubber Precision performer is a high efficiency and high precision rubber blanks (rubber preforms) preparation equipment. Application in wide field of rubber industry,it can cut many kinds of middle or high hardness of rubber preforms in desired shape and exact weight. The rubber preforms machine is suitable for production of various kinds of rubber parts,such as oil seals, valves, stoppers, tennis balls, O ring seals, shoe soles,ect.

Rubber Precision preforming machine mainly compose of functions of vacuum, filtration, extrusion, cut, weigh, adopts humanized design, easy and safe operation.

Introduction of rubber precision performer:

1. The rubber precision pre-forming machine cuts the compounded rubber into the required shape and weight, and the weight accuracy of the rubber blank (rubber preforms) can be controlled within ±1%.

2. PLC control, processing parameters are stored, direct call, easy operation.

3. The oil cylinder and the material barrel adopt the detachable structure to prevent the rubber material from entering the oil cylinder and extend the service life of the rubber preforms machine.It is convenient to replace the rubber material and easy to clean.

4. The conveyor net cover is made of stainless steel to prevent rubber pollution.

5. Electronic scale loop circuit feedback matches with PLC, one-click calibration of rubber blank weight.

6. The equipment fault alarm and icon display the fault location, and regularly remind workers to check and calibrate the weight of the rubber blank (rubber preforms).

7. Piston/machine head/blade and other units of the rubber preforming machine are interlocked to provide all-round protection,effectively avoiding the occurrence of injuries.

8. The barrel is equipped with an LED extension lamp, which is convenient for cleaning and avoids the situation where the dead angle is not cleaned in place.

9. The rotary vane vacuum pump effectively draws out the air in the barrel, further ensuring the weight accuracy of the rubber blank and improving the quality of the rubber blank.

10. The plunger is pushed in flat direction, and almost no heat is generated during the propulsion process, to avoid the occurrence of rubber burning.

11. The system pressure and extrusion pressure are digitally displayed on the touch screen.

12. The system pressure and extrusion pressure are digitally displayed on the touch screen.

13. Disassembly of mouth piece (nozzle/ mold) at the front of the machine head, without needing to open the machine head, it is convenient and fast, reduces labor intensity and improves efficiency.

14. Water circulation heating (heat preservation function to avoid uneven heating inside and outside the rubber roll), excellent temperature distribution and stability.

15. The machine head is completely sealed with stainless steel (SUS304) to prevent the rubber from spilling to the ground (spilling the ground to pollute the environment and waste the rubber, etc.)

16. The conveyor is forward and reverse to distinguish between qualified and unqualified rubber preforms in the initial stage.

17. As the advanced cooling system is adopted for our rubber preform machine, the machine operates for 24 hours,the temperature of the hydraulic oil won't exceed 50°C,which ensures the stability of the hydraulic system..

Technical specification for rubber preforms making machine:

|

Model |

JYZ-150 |

JYZ-200 |

JYZ-250 |

JYZ-250+ |

|

Barrel diameter |

150 mm |

200 mm |

250 mm |

250MM |

|

Total power |

15kw |

15 kw |

22kw |

26 kw |

|

Max.oil cylinder pressure |

36.8 Mpa |

21 Mpa |

20.7 Mpa |

20.7 Mpa |

|

Max.barrel temperature |

|

|

|

|

|

Max. die diameter |

80 mm |

125 mm |

190 mm |

190 mm |

|

Rubber bland weight range |

0.3~100 g |

0.3~ |

0.3~ |

0.3~ |

|

Rubber blank weight precision |

±1.0﹪ |

±1.0﹪ |

±1.0﹪ |

±1.0﹪ |

|

Feed capacity per batch |

10~15 kg |

20~25 kg |

60~70 kg |

100~110 kg |

|

Blade rotation speed |

35~400 R/M |

35~400 r∕min |

35~400 r∕min |

35~400 r∕min |

|

Dimension(L×W×H:m) |

4.1×1.21×1.73 |

4.1×1.21×1.73 |

5.3×1.21×1.73 |

6.5x1.21x1.73 |

|

Weight |

2.8 T |

3 T |

4T |

5T |