Spin-trim type Rubber Deflashing Machine (Rubber O Ring Deburring Machine)

--Spin-trim type Rubber Deflashing machine unit

--Spin-trim type Rubber Deflashing machine unit

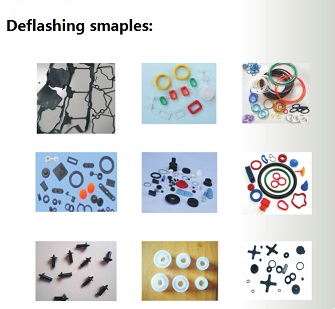

--The rubber samples that this spin-trim type rubber deflashing machine can treat.

--The rubber samples that this spin-trim type rubber deflashing machine can treat.

By using the theory of aerodynamic and centrifugal force, the Spin Trim type Rubber Deflashing Machine (Rubber Deburring Machine) is developed to make the flash and rubber

Highlights:

1. PLC programming control, touch-screen human-machine digital operation, store all kinds of production process, parameters of each product.

2. Precisely controlled demolition speed, operating performance is simple, intelligent, working sound is low, greatly reduces the operator fatigue.

The rubber de-flashing machine has independent feeding position and working station, no need to stop machines every time when feeding, achieving continuous flow operation.

3. Power consumption is only around 4 KW per hour, more importantly,the type rubber parts deflashing machine can remarkably reduce labor force, saving workforce cost,

greatly improve production efficiency, the production capacity of one this machine is equivalent at least 50 times of workers’ manual production.

Besides this machine won’t do deformation, damage, dirt to the processed rubber.

4. No need to change any mold or any parts for our rubber deflashing machine (rubber parts deburring machine).

1. NMI-356 Spin-trim type Rubber Deflashing machine:

|

Model |

NMI-356 |

|

Spin-chamber capacity |

18 Liter |

|

Diameter of spin-chamber |

356mm |

|

Max.spinning speed |

10000 RPM (adjustable) |

|

Operation time/batch |

Depends on different rubber parts, Cycle time adjustable |

|

Motor |

4KW |

|

Variable-frequency Drive |

5.5KW |

|

Electronic control system |

PLC+Touch screen control, automatic storage operating system. |

|

Water spraying function |

Automobile-grade automatic water spraying function. |

|

Fresh air system: |

Compressed air-cooling device |

|

Transmission system |

①Aviation grade aluminum V-ribbed pulley. ② Automobile grade American gates conveyor belts. ③ High-speed bearings imported from Germany.

|

|

Working Noise |

insulated for sound reduction |

|

Dimension |

L1330*W650*H900mm |

|

Weight |

350 KGS |

2.NMI-406 spin-trim type Rubber Deflashing machine:

|

Model |

NMI-406 |

|

Dimension |

L1450*W700*H1000mm |

|

Spin-chamber capacity |

22 Liter |

|

Diameter of spin-chamber |

406 mm |

|

Max.spinning speed |

10000 RPM (adjustable) |

|

Operation time/batch |

Depends on different rubber parts, Cycle time is adjustable |

|

Motor |

5KW |

|

Variable-frequency Drive |

7.5KW |

|

Electronic control system |

PLC+Touch screen control, automatic storage operating system. |

|

Water spraying function |

Automobile-grade automatic water spraying function. |

|

Fresh air system: |

Compressed air-cooling device |

|

Transmission system |

①Aviation grade aluminum V-ribbed pulley. ② Automobile grade American gates conveyor belts. ③ High-speed bearings imported from Germany.

|

|

Working Noise |

insulated for sound reduction |

|

Dimension |

L1450*W700*H1000mm |

|

Weight |

400 KGS |

3.Vibration screen separator:

|

Application |

Separation of burrs (unwanted flash) from the good rubber parts |

|

Explosion-proof professional vibration motor |

0.18 KW |

|

Spring cushion |

Special spring rubber combined buffer device |

|

Replaceable mesh screens |

10 PCS |

|

Dimension |

L1250*W600*H600mm |

|

Weight |

100 KGS |